Why Choose ABM

Vacuum Heat Treatment

ABM applies vacuum heat treatment to every bearing. Vacuum heat treatment results in excellent metallurgical structure for bearing rings.

This is the foundation of success of every durable ABM bearing.

Grinder

Grinder is the most used machine tool in bearing industry. Since 1994, ABM has been developing our own grinder technologies which include grinder overhaul, retrofit, and modernization. All manufacturing procedures, including the grinder reassembly, rewiring, and controller program updating, are centralized and completed at ABM to ensure quality and efficiency.

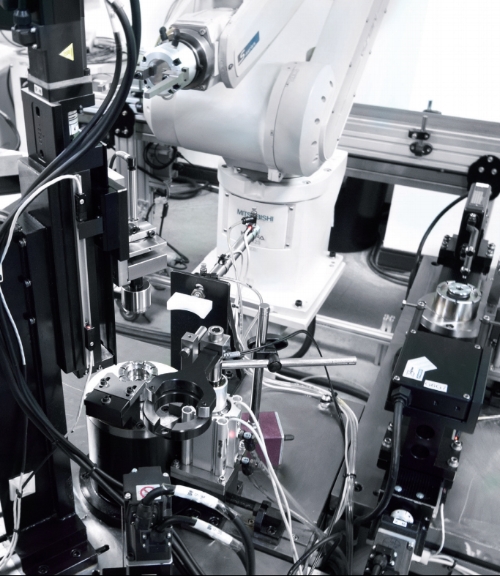

Automation

Tailor-made automation for bearing runout check, dimension measuring, and assembly are designed and manufactured at ABM. Those automation systems are integrated with 6 axis articulate robots and various linear gauges and can conduct quality check with 100% accuracy.

Super Finishing

Every bearing raceway undergoes one machining process after grinding called “super finishing”.

This process significantly perfect the surface texture of bearing raceway. Ra 0.01μm surface roughness is our only standard for super finishing result.